Sino Holdings Group is famous for plastic

mould supplier (SINO MOULD) both at home and abroad, and recent years, as its custom

plastic injection machine with high efficiency and energy saving, one

of the members, Dakumar Machinery Co., Ltd. (DKM) is being popular and reputed

in our partners.

|

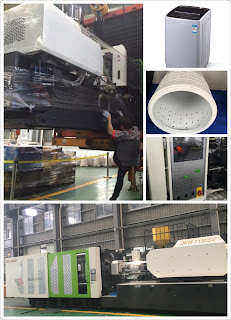

| DKM FACTORY FOR INJECTION MACHINE |

When people are looking for injection machine,

the first is model, which should match their moulds, and base on this, they

must pursue particularly good value for money of machine, so that their production

line will be more efficient. And exactly to satisfy our partners, DKM apply top-class

components in machine, like computer is KEBA, kinds of switch is OMRON, and

breaker is Schneider, etc.

Custom injection molding machine can be

offered for your product, for example, as the injection machine for making

household appliance, like, refrigerator inner cabinet liner. The basic info is

about container’s size, weight, plastic material, and special structure, which

will affect the design of machine:

Size and weight → model of

injection: injection weight, clamping tonnage, tie-bar distance, etc.

Plastic → screw of

machine, such as, if the material is PC for container, then we should use

special screw for it, as PC owns poor flow characteristics and takes in moisture

easier, then the molding will be easier than normal screw.

Special

structure → special action of mould → component of

machine, like, if need to add additional air valve, lateral sliding.

More info, welcome to talk:

Lucy

sales9@sinomould.com

+8615757605003 (WhatsApp, online service for you)

anole-hc-01 (skype)