Starting a new factory for making medical

syringe is required much. Except the license for allowing to manufacture the

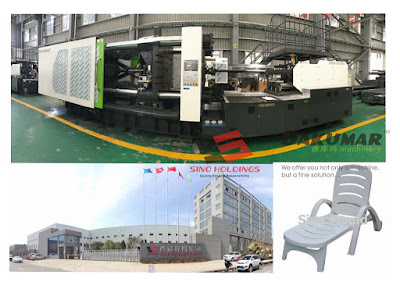

syringe, there are much things that SINO HOLDINGS GROUP can help do to support

your.

Kindly visit the video here, you can find

that if you’d like, everything SINO could offer as a support, after all, SINO

is engaged in offering injection mould and machine solution. But for the

syringe making line, there are solutions offered successfully, so you can trust

and try to find how the solution is.

As video showed, you must find there are 5

parts for producing the syringe:

1. Injection molding for syringe set, including syringe barrel, syringe

plunger, syringe gasket, syringe top cap, syringe hub (needle seat), which need

moulds and injection machines.

2. Printing barrels by machine

3. Assembling syringe sets by automatic line (which can also need needle

assembly machine)

4. Packaging syringe

5. E.O Gas Sterilizer Machine

Looks so nice, with little labor but full-automatic

making line for syringe, isn’t it? So if you’d like to setup a plant for

producing them by yourself, kindly contact me.

Details can be show if you’d like, anyway,

Lucy is always here for you.

Lucy

+8615757605003 (WhatsApp, online service

for you)